Latest Blog Articles

A Comparison of Space-Grade Memory Technologies

Satellite and spacecraft sub-systems are increasingly using more and more on-board storage, and the choice of memory has a major impact on overall capacity, physical size, power-consumption, speed, reliability and mission lifetime. One technology is fabricated with known erroneous bits, with limits on the total number of permitted write operations, which could constrain or jeopardise your mission’s on-board storage needs! SDRAM, MRAM, NAND flash, NOR Flash, SONOS, SRAM, PROM, DRAM, EEPROM, volatile, non-volatile and SPI memory, which one is right for you?

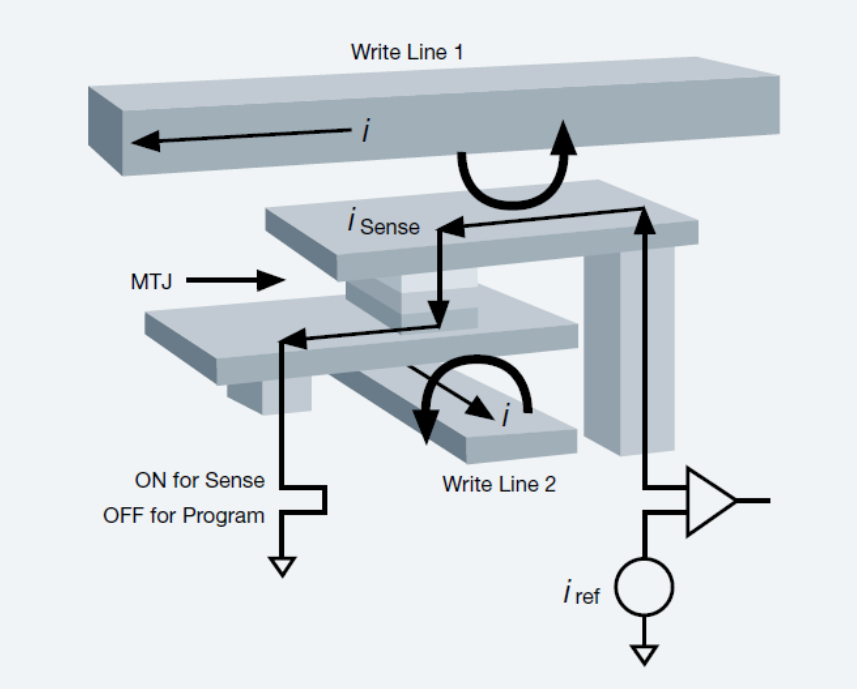

Fast, High-Capacity, Endurant MRAM for Space Applications

MRAM offers the space industry the speed of SRAM, a density approaching DRAM, the non-volatility of flash memory, unlimited read/write endurance and low power consumption. These on-board storage benefits will enable new use cases for satellite applications.

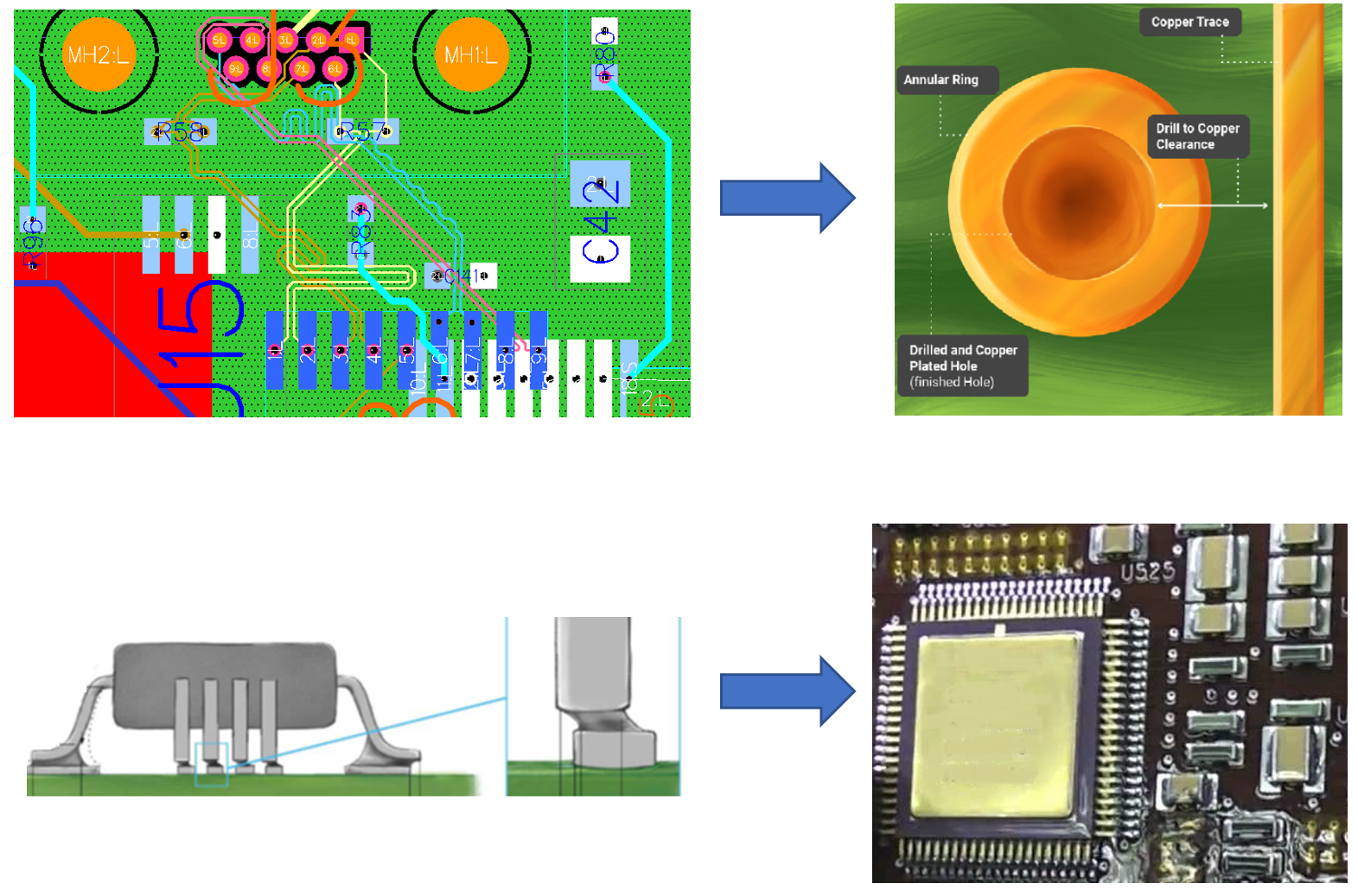

DFM & DFA : Building Your Space-Grade PCB Right-First-Time

Your customer wants tested hardware next month and you have budget for a single PCB spin: before sending your ODB++ or Gerber artwork, there are important Design-for-Manufacturing (DFM) checks to ensure your layout complies with formal standards, the fabricator can make it and your new bare-board is returned right-first-time. There are also Design-for-Assembly (DFA) checks to verify your sub-contractor can reliably place parts onto the PCB - I will not sign-off a new build until DFM and DFA have passed!

Older Select Blog Posts

Rajan’s award-winning blog on Space Electronics, Out-of-this-World Design, is being read by 19,000 people every month and has been viewed almost eight million times. Articles have been hosted by EDN since 2013 and selected posts can be viewed by hovering and clicking the images below:

New Company of 2017 and High-Reliability Product of 2017

High-Reliability Product of 2016

International Company of 2018

Top 100 StartUp

Wolfram

Oct 06, 2025 10:00:27Kenneth Wilson

Jul 14, 2022 03:58:06